The Real Strength of Ripstop Nylon Drawstring Bags

TL;DR

A ripstop nylon drawstring bag offers an exceptional strength-to-weight ratio, making it a highly durable choice for its minimal bulk. The fabric's signature grid of reinforcement threads prevents small punctures from turning into major tears. However, the bag's overall strength and how much weight it can hold ultimately depend on factors like the fabric's denier (thickness) and, most critically, the quality of the stitching and seams.

Understanding Ripstop Nylon Strength: Key Metrics

At first glance, ripstop nylon looks like any other lightweight fabric, but its true strength lies in its unique construction. Developed initially for military parachutes, this material incorporates a special reinforcing technique where thicker, stronger yarns are interwoven at regular intervals in a crosshatch pattern. This grid is the key to its durability; if a puncture does occur, the tear is stopped by the nearest reinforcement thread, preventing catastrophic failure. This design makes it fundamentally different from standard nylon, which can rip completely once compromised. Ripstop fabric is engineered to provide exceptional durability while remaining lightweight, making it ideal for applications where strength is crucial without adding bulk.

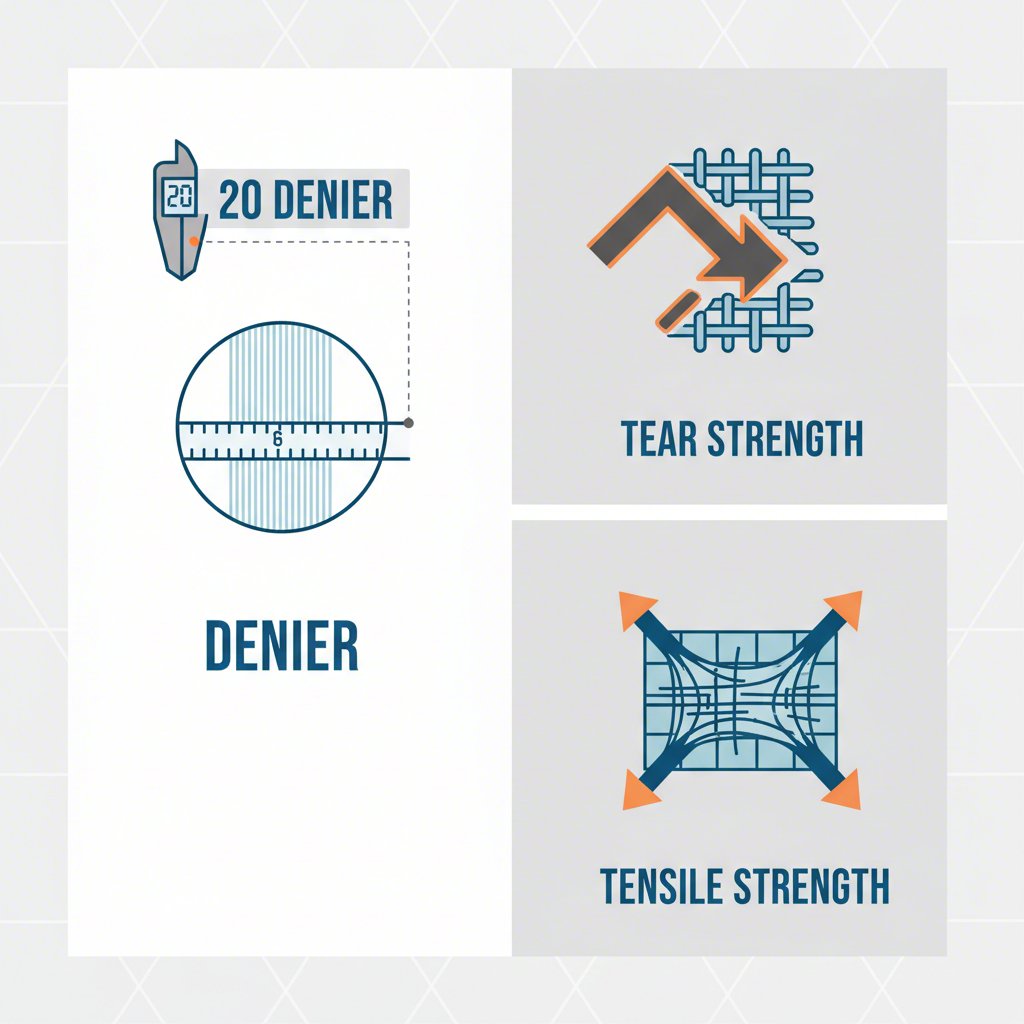

To accurately gauge the strength of a ripstop nylon drawstring bag, it's essential to understand the technical terms used to measure fabric performance. These metrics provide a standardized way to compare different materials and determine their suitability for various tasks. When you see these specifications on a product tag, they offer a clear picture of the bag's potential durability and resilience.

Denier (D): This is a unit of measurement for the thickness or density of individual fibers. A lower denier, like 40D, indicates a very lightweight, packable fabric suitable for ultralight bags. A higher denier, such as 210D or 400D, signifies a heavier, more robust fabric designed for greater wear and tear.

Tear Strength: This measures the force required to propagate an existing tear. The ripstop weave dramatically increases tear strength. For example, some 30-denier ripstop fabrics have a tear strength of around 15 lbs, meaning it takes significant force to worsen a small rip.

Tensile Strength: This is the maximum stress a material can withstand while being stretched or pulled before breaking. Lower denier ripstop can have a tensile strength between 350 to 500 Newtons (N), while heavier versions are significantly stronger. This metric indicates the fabric's ability to handle heavy loads without pulling apart.

Abrasion Resistance: This refers to the fabric's ability to resist damage from rubbing against rough surfaces. While ripstop's primary advantage is tear resistance, its abrasion resistance is generally moderate and increases with a higher denier. For extreme abrasion, materials like Cordura often outperform ripstop, but for a drawstring bag, ripstop offers a fantastic balance of all-around durability.

Practical Application: How Much Weight Can a Bag Really Hold?

While the technical specifications of ripstop nylon are impressive, the most practical question is: how much can you actually carry in one of these bags? The fabric itself is remarkably strong. As an extreme example, some 1.1 oz ripstop fabrics used in camping hammocks are rated with a comfort limit of 200 pounds. This demonstrates the incredible load-bearing potential of the material itself. However, for a drawstring bag, the fabric's strength is rarely the limiting factor. The real-world capacity is almost always determined by the quality of its construction.

The weakest points on any bag are its seams, stitching, and hardware. A bag made from high-strength ripstop can still fail under a heavy load if the seams are poorly stitched. Overloading can cause threads to pull, seams to burst, or grommets for the drawstring to tear out long before the fabric itself is compromised. This is why evaluating the overall build quality is just as important as checking the fabric type. When choosing a bag, don't just rely on the material specs; inspect the craftsmanship closely.

For global wholesalers and suppliers seeking high-quality custom promotional items, understanding these construction details is key. Companies like Bincai Import and Export Co., LTD specialize in bespoke sewing products, offering over 15 years of expertise in creating custom drawstring bags. They can help ensure that design elements like reinforced seams and durable hardware are incorporated, matching the construction quality to the strength of the ripstop material for bulk orders.

To ensure you're selecting a well-made bag that can handle its intended load, look for these signs of quality construction:

Reinforced Stitching: Check for bar tacks (a series of tight, reinforcing stitches) at high-stress points, such as where the drawstrings connect to the bag.

Double-Stitched Seams: High-quality bags often feature double stitching along the main seams to distribute stress and prevent separation.

Durable Hardware: The drawstring cord itself should be thick and sturdy, and if metal grommets are used, they should be securely fastened without any signs of fabric tearing around them.

Internally Bound Seams: Look inside the bag. Seams that are covered with an extra strip of fabric (bound seams) are more durable and less likely to fray over time.

Ripstop Nylon vs. Other Materials: A Strength-to-Weight Showdown

Ripstop nylon's primary advantage is its outstanding strength-to-weight ratio, but it's not the only material used for bags. Understanding how it compares to other common fabrics helps clarify when it's the best choice for your needs. Each material offers a different balance of durability, weight, and resistance to various types of wear, making them suitable for different applications.

For instance, Cordura is another high-performance synthetic fabric renowned for its durability. However, it achieves its strength through sheer thickness and a dense weave, making it significantly heavier and less packable than ripstop. While Cordura excels in abrasion resistance, making it ideal for heavy-duty luggage or tool bags, ripstop's grid system provides superior protection against tears spreading in a lightweight package. Standard nylon, without the ripstop grid, is strong but can easily tear from end to end once punctured. This makes ripstop a clear upgrade for any application where tears are a concern.

The following table provides a clear comparison of common materials used for drawstring bags, highlighting their key performance characteristics:

| Material | Tear Strength | Abrasion Resistance | Weight | Primary Advantage |

|---|---|---|---|---|

| Ripstop Nylon | Excellent (grid stops tears) | Moderate to Good | Very Low | Exceptional strength-to-weight ratio |

| Cordura | Good | Excellent | High | Superior abrasion resistance and structure |

| Standard Nylon | Poor (tears can spread) | Good | Low | General-purpose strength and affordability |

| Canvas/Cotton | Fair | Good | High | Natural feel and eco-friendly properties |

| Leather | Excellent | Excellent | Very High | Maximum durability and classic aesthetic |

Ultimately, the choice depends on the bag's intended use. For an ultralight gym bag, a packable travel sack, or an everyday tote where preventing a small snag from becoming a big problem is key, ripstop nylon is an ideal solution. For applications demanding extreme ruggedness and resistance to constant scraping, a heavier material like Cordura may be more appropriate. For users prioritizing natural materials, canvas remains a strong, albeit heavier, alternative.

Frequently Asked Questions

1. What is the strength of ripstop nylon?

The strength of ripstop nylon comes from its composite structure. While the base fabric has good tensile strength (often 350-500 N for lighter weights), its defining feature is the interwoven grid of thicker threads. These threads act as tear-stoppers, meaning a puncture won't easily spread, giving the fabric exceptional durability for its weight.

2. How much weight can ripstop fabric hold?

The fabric itself can hold a significant amount of weight, with some variants used in hammocks supporting over 200 lbs. However, a ripstop drawstring bag's practical weight limit is determined by its construction. The stitching, seams, and drawstring anchor points are typically the first areas to fail under a heavy load, not the fabric.

3. How strong is a nylon bag?

Nylon, in general, is a very strong and resilient synthetic fiber. A standard nylon bag is known for its toughness, resistance to abrasion, and ability to hold its shape over years of use. Ripstop nylon enhances this inherent strength by adding a specialized weave that provides superior tear resistance, making it one of the most durable lightweight options available.

4. What are the disadvantages of ripstop nylon?

While highly durable, ripstop nylon has a few downsides. It can absorb moisture if not treated with a waterproof coating, which can make it heavy. Additionally, its abrasion resistance, while good, is typically lower than that of heavier fabrics like Cordura. Finally, it can sometimes be more expensive than other synthetic options like polyester.

售前客服

售前客服