Screen Printing vs Embroidery: The Right Choice for Bags

TL;DR

Choosing between screen printing and embroidery for drawstring bags hinges on your priorities. Screen printing is the ideal choice for large orders with complex, multi-color designs, offering cost-effectiveness and high detail. Conversely, embroidery provides a durable, premium, and textured finish, making it perfect for smaller logos, high-end branding, and orders where longevity is more important than the initial cost.

Key Differences at a Glance: Screen Printing vs. Embroidery

Understanding the fundamental differences between screen printing and embroidery is the first step to making an informed decision for your drawstring bags. Screen printing involves pushing ink through a stenciled mesh screen onto the fabric, creating a smooth, flat design. Embroidery, on the other hand, uses high-tech machinery to stitch a design directly into the fabric with thread, resulting in a textured, three-dimensional look. Each method has distinct advantages depending on your project's specific needs.

To simplify your choice, here is a direct comparison of the most important factors:

| Feature | Screen Printing | Embroidery |

|---|---|---|

| Best For | Large orders, detailed/photorealistic graphics, promotional giveaways, t-shirts, and lightweight bags. | Corporate branding, uniforms, high-end merchandise, simple logos, and thicker fabrics like hats and jackets. |

| Cost | Lower per-unit cost on bulk orders. Price is affected by the number of colors used. | Higher per-unit cost. Price is determined by stitch count, not the number of colors. |

| Durability | Durable, but ink can crack or fade over many washes and years of use. | Extremely durable; the thread is fade-resistant and often outlasts the bag itself. |

| Appearance | Smooth, flat, and vibrant. Excellent for capturing fine details and color gradients. | Textured, raised (3D), and professional with a high perceived value. |

| Design Complexity | Ideal for intricate, multi-color, and complex designs, including photographs. | Best for simple, bold designs and text. Cannot replicate gradients or fine details well. |

| Fabric Compatibility | Works well on most fabrics, especially cotton and polyester blends like those used in drawstring bags. | Best on heavier, sturdier fabrics. Can cause puckering on very lightweight materials. |

If your primary need is producing a large number of bags for an event on a budget, the table points toward screen printing. If you are creating a premium product where a durable, high-end feel is essential, embroidery is the clear winner.

Cost Analysis: Budgeting for Your Drawstring Bags

One of the most significant factors in choosing between screen printing and embroidery is the cost. While it's easy to say one is generally cheaper, the reality depends heavily on your order's specifics. Screen printing is typically more cost-effective for large quantities, whereas embroidery can be surprisingly economical for smaller runs with simple designs.

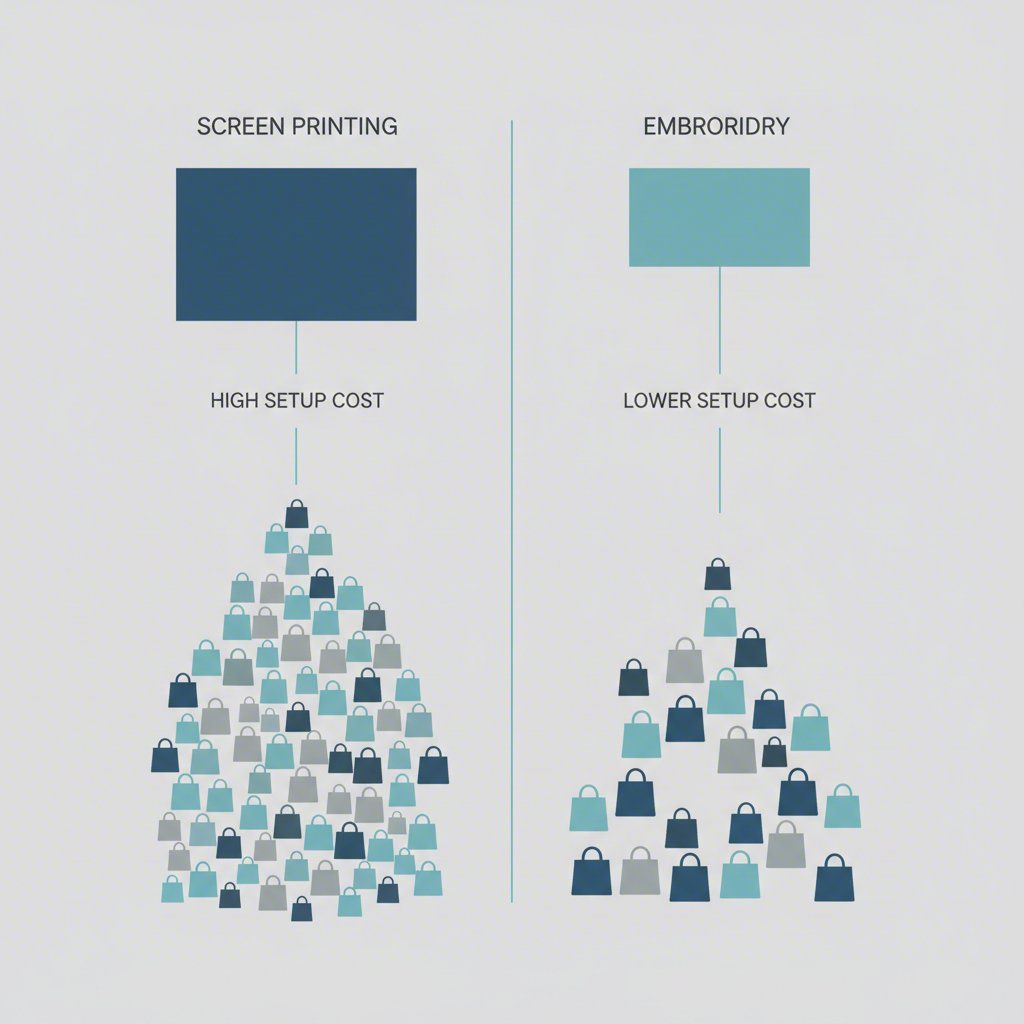

The pricing model for screen printing is based on the number of colors in your design. Each color requires a separate screen to be created and set up, which involves a significant initial cost. However, once the screens are made, the cost per bag becomes very low. This is why screen printing is the go-to method for bulk orders; the high setup cost is distributed across hundreds or thousands of items, making the per-piece price minimal. For an order of 200 drawstring bags with a three-color logo, screen printing will almost always be the more budget-friendly option.

Embroidery, in contrast, is priced based on the design's stitch count. A larger or more complex design requires more stitches and more time on the machine, which increases the price. The number of thread colors has little to no impact on the cost. This model makes embroidery suitable for small orders, like a dozen high-quality bags for a corporate team, where the lack of color-based setup fees can make it competitive. The initial 'digitization' fee—converting your design into a stitchable file—is a one-time cost that makes reordering simple and efficient.

For global wholesalers and suppliers looking to produce custom promotional items in large volumes, understanding these cost structures is key. Companies like Bincai Import and Export Co., LTD, which specialize in bespoke sewing products and bulk orders, can help navigate these decisions to maximize your budget. When planning your project, consider these key questions:

Order Quantity: Are you ordering 20 bags or 2,000?

Design Colors: Is your logo one color or a full-color photograph?

Design Size: Is it a small chest logo or a large back graphic?

Answering these will quickly reveal whether screen printing's scale efficiency or embroidery's stitch-based pricing is better suited for your budget.

Durability & Longevity: Which Customization Lasts Longer?

When you invest in custom drawstring bags, you want the branding to last. This is where embroidery has a distinct and significant advantage. According to experts at RushOrderTees, an embroidered design will typically outlast the garment it's stitched on. This exceptional durability comes from the process itself: threads are stitched directly *into* the fabric, becoming an integral part of the bag.

This physical integration means embroidered logos are highly resistant to the rigors of daily use, including friction, sun exposure, and repeated washing. The high-quality thread used is colorfast, ensuring the design won't fade over time. This makes embroidery the superior choice for items intended for long-term use, such as team sports bags, employee gear, or high-end retail products. The design will remain crisp and professional for years, reflecting a continued standard of quality.

Screen printing, while durable, operates differently. The ink is applied *on top* of the fabric and then heat-cured to bond with the fibers. While modern inks and curing processes create a strong, lasting print, it is still a surface-level application. Over time, with extensive washing and wear, the ink can be susceptible to cracking, peeling, or fading. This is especially true if the bag is frequently folded along the design or washed in harsh conditions.

However, for many applications, the durability of screen printing is more than sufficient. For promotional giveaway bags at a trade show or a one-time event, the print will easily last for the intended lifespan of the item. The choice comes down to purpose. If the drawstring bags are meant to be long-lasting symbols of your brand, the investment in embroidery's superior longevity is well worth it. If they are for short-term promotional impact, screen printing offers a durable and cost-effective solution.

Design & Appearance: Achieving Your Desired Look

The final look and feel of your drawstring bags are profoundly influenced by your choice of decoration. Screen printing and embroidery produce vastly different aesthetics, each suited to different branding goals and design types. Your decision should align with the visual identity you want to project.

Screen printing is the champion of detail and color. Because it uses ink, it can replicate intricate graphics, fine lines, and photorealistic images with remarkable precision. As noted by Mint Printworks, screen printing is the clear choice for any design with gradients or shading, effects that are impossible to achieve with thread. The result is a smooth, flat finish that feels integrated with the fabric, creating a bold, graphic look. If your design is a complex illustration, a photograph, or contains many colors, screen printing is the only way to capture its full detail on a drawstring bag.

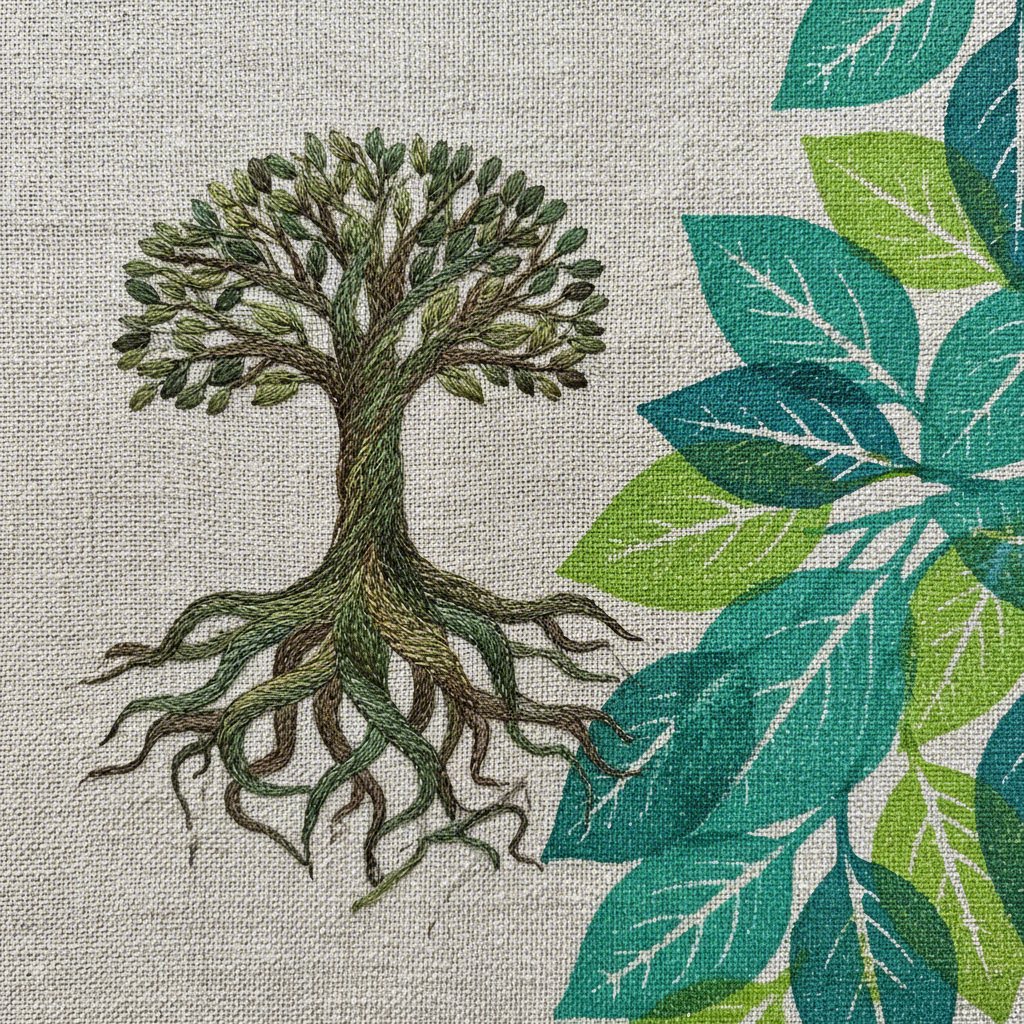

Embroidery, conversely, excels at creating a sense of quality, texture, and dimension. The stitched threads create a raised, 3D effect that has a high perceived value. It conveys professionalism and permanence, making it a favorite for corporate logos and premium brands. The slight sheen of the thread catches the light, making the design pop in a subtle, sophisticated way. However, this method has limitations. The physical nature of thread means it cannot reproduce fine details, small text, or color gradients effectively. Designs for embroidery must often be simplified, focusing on bold shapes and distinct color blocks.

Think of the difference this way: screen printing is like a high-quality poster, while embroidery is like a sculpted emblem. Consider your fabric as well. Embroidery works best on sturdy materials that can support the stitch density without puckering, whereas screen printing is versatile across a wider range of fabrics, including the lightweight polyester common in drawstring bags. For a classic, professional logo on a corporate gift bag, choose embroidery. For a bag featuring a vibrant, detailed piece of artwork, choose screen printing.

The Verdict: Which Method Is Best for Your Drawstring Bags?

Ultimately, the best choice between screen printing and embroidery for your drawstring bags is not about which method is superior overall, but which is perfectly suited to your specific project. By evaluating your priorities—budget, order size, design complexity, and desired aesthetic—you can make a confident and effective decision. Both methods produce high-quality results, but they serve different purposes.

To make it simple, follow this scenario-based guide to determine your ideal match.

Choose Screen Printing if...

You have a large order: If you're producing 50 or more bags, screen printing's economies of scale will provide the best value.

Your budget is a primary concern: For promotional events, giveaways, or large-scale distribution, screen printing is the most cost-effective option.

Your design is complex or colorful: If your artwork includes intricate details, gradients, photographs, or more than a few colors, screen printing is the only method that can reproduce it accurately.

You need a fast turnaround: The screen printing process is generally faster for bulk orders once the initial setup is complete, as highlighted by 4AllPromos.

Choose Embroidery if...

You want a premium, high-end look: The textured, 3D finish of embroidery conveys quality and professionalism, making it ideal for corporate gifts or high-end merchandise.

Durability is your top priority: If the bags are intended for long-term, repeated use, embroidery's stitched-in design will outlast any print.

Your design is a simple logo or text: Embroidery excels with bold, clean designs where its texture can shine without being cluttered by excessive detail.

You have a smaller order quantity: For small batches, the per-piece cost of embroidery can be comparable to or even better than screen printing, as its pricing is based on stitch count rather than color setups.

By aligning your needs with these guidelines, you can ensure your final product not only looks great but also perfectly fulfills its purpose, whether that's maximizing brand exposure at an event or providing a durable, premium item to a valued client.

Frequently Asked Questions

1. What lasts longer, screen print or embroidery?

Embroidery is significantly more durable than screen printing. Because the design is stitched directly into the fabric, it becomes a permanent part of the item. An embroidered logo is resistant to fading, cracking, and peeling, and will typically last longer than the bag itself. Screen-printed designs are durable for normal use but can degrade over many years and washes as the ink is a layer on top of the fabric.

2. Is embroidery or screen printing cheaper?

Screen printing is generally cheaper for large orders, especially those with fewer colors. The main cost is in the initial setup of the screens; once that's done, the price per item is very low. Embroidery is often cheaper for small orders with simple logos because its cost is based on the number of stitches, not the number of colors. For a few items, avoiding the high setup fees of multi-color screen printing makes embroidery more economical.

售前客服

售前客服